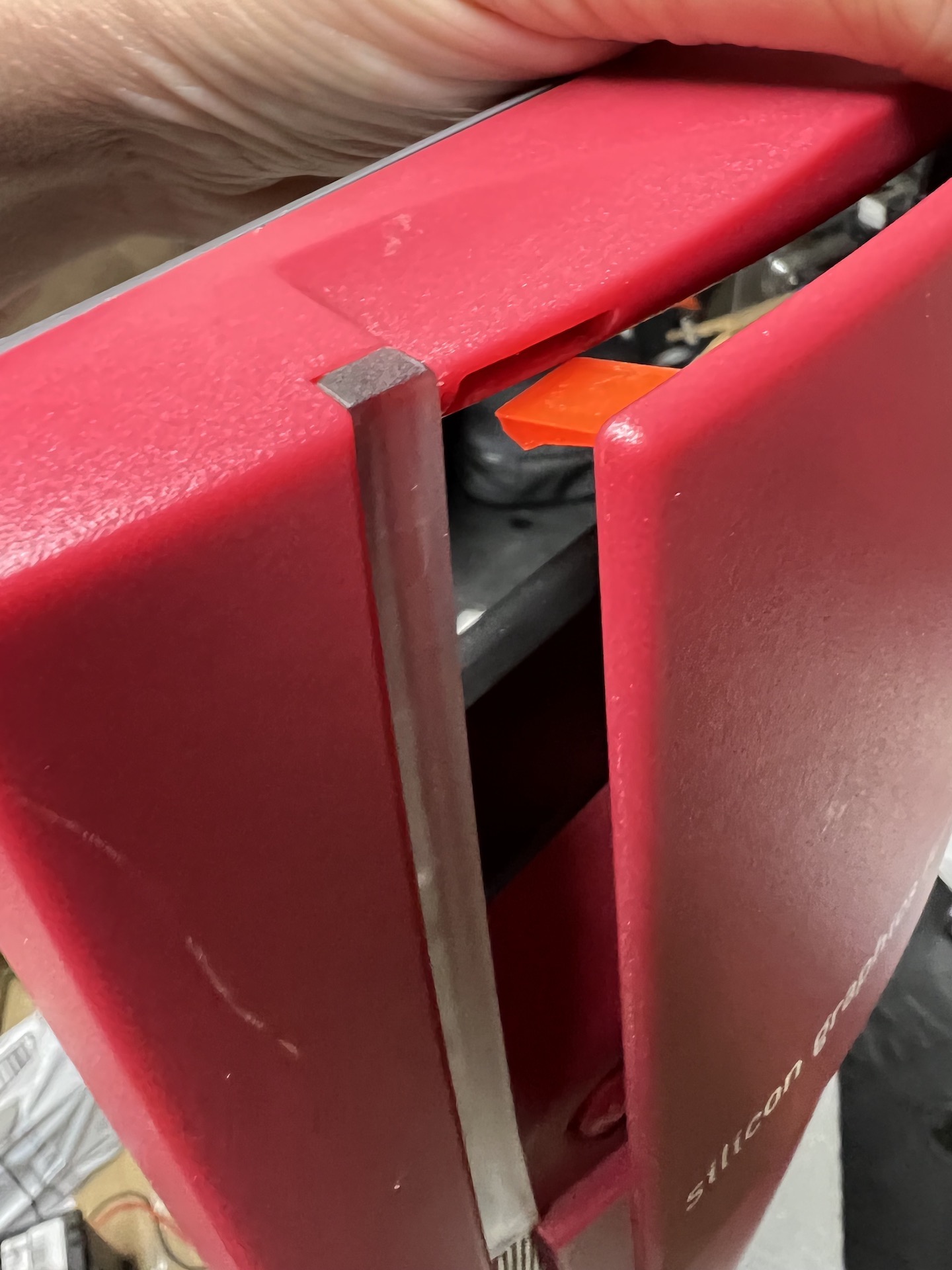

Okay, update. Everything is dried/bonded so I went to do a test close...problems.

When everything is lined up and flat...it points DOWNWARDS and misses the slot...ughhhh. I asked my friend that did the printing what the temps should be used slightly bend this piece without it melting on me. He suggested 150F, I set a heat gun to 140F and gently went around it, stopping every 20 seconds or so to touch it with a metal implement to test of bending. Within about 2 minutes it was able to bend it at the thin part.

I removed heat and pushed th 3D printed latch up several times (small amounts) for about 15 seconds (no heat remember), testing the latch by almost closing the door and seeing where it was going to hit then after 30 seconds I shut the door (closed), waited for another 10 seconds and then opened the door.

Before I had to "lift" the door to get it into the slot and work, now the latch hits the very bottom of the slot and rides up (door moves up slightly) correctly and latches everytime!

So success! However after gluing I had to soften the 3D print to "angle it" by bending the joint upwards slightly..I'd say around 1/8 of an inch or less (slight).

But it had to be done or I couldn't push the door closed! Now you can push and it all latches (tightly) without wiggle.

So be prepared to use a temp-controlled hot air device to "rework" the part's alignment, once glued down.

NEED ->

NEED ->