Hey Guys,

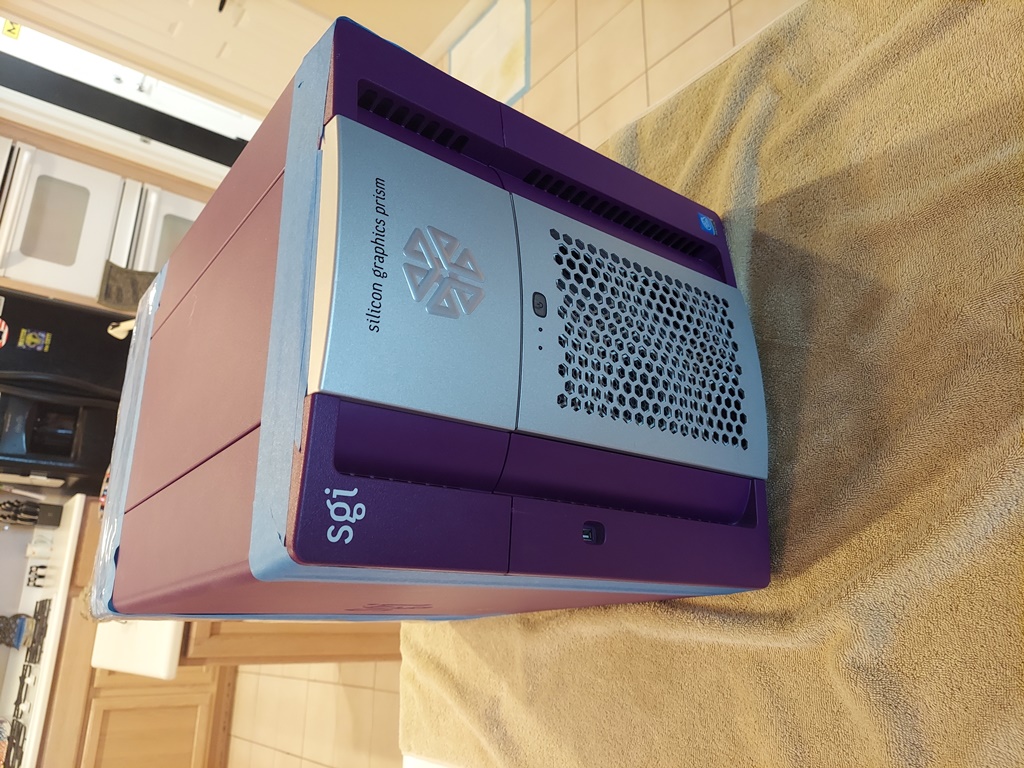

I wanted to give my suggestions for shipping SGIs. This was a Prism that I admit is not one of the most fragile machines but it's rarity still warrants the extra effort.

This same process works very well with Tezros and Octanes as I ship them on their back as well. The metal structure of the back when packed well can easily withstand the shipping forces involved.

Thanks,

John

Before you start take very detailed photos of the machine from all angles!!! This includes any serial and part numbers!! Then take photos of each step of the packing process like you see here! Most people involved in this hobby are good people, but there are some scammers out there who will claim that you didn't ship what was advertised. The photos help your case. Also, most shippers try to insist that they pack the machine for insurance reasons. I have found that the ones I deal with will accept the photos as proof of secure packing.

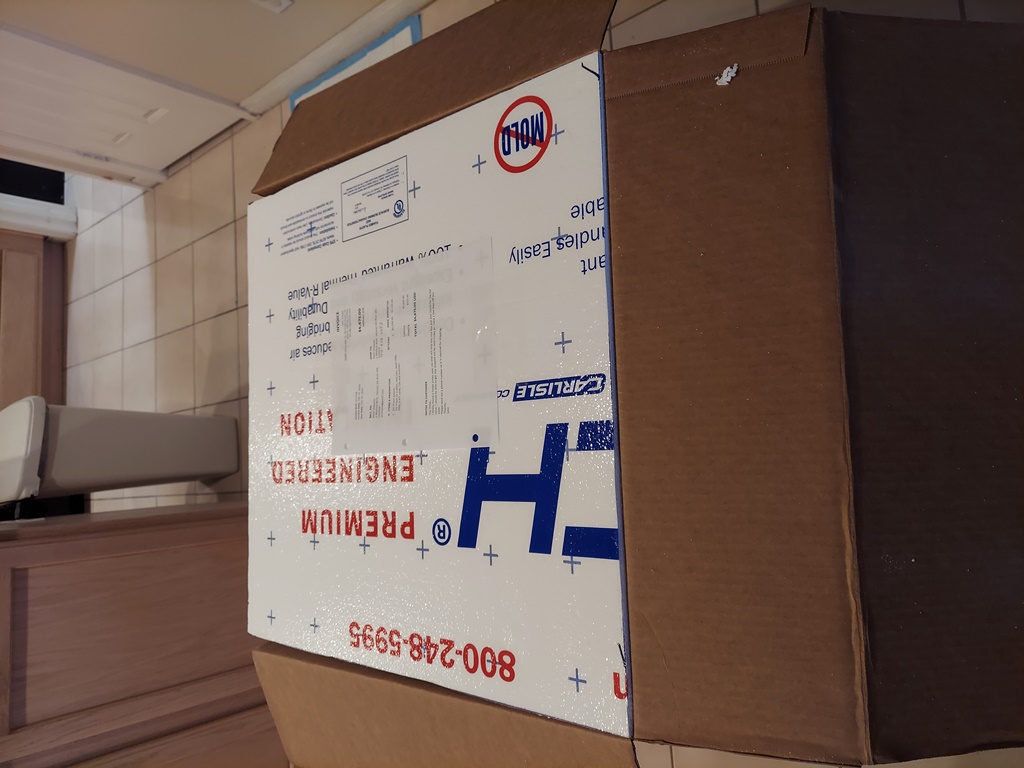

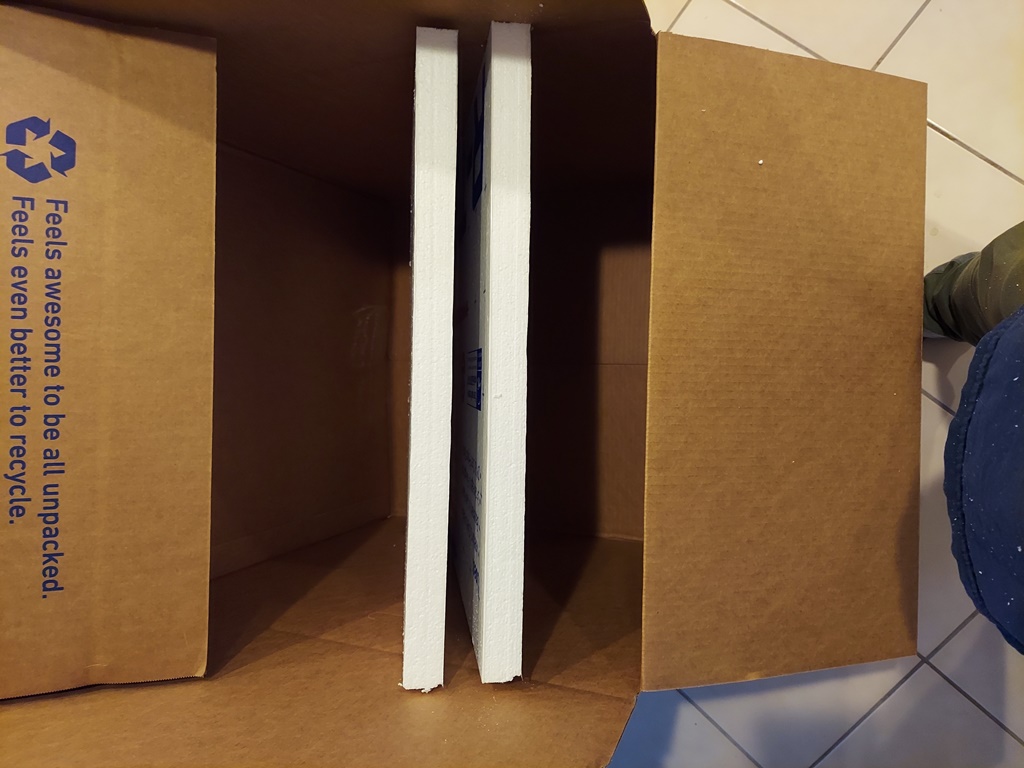

I start with a 24x24x32" box and put two 1.5" thick pieces of Styrofoam board on the bottom as a base. This material is sold by building supply places in 4'x8' sheets, is easy to cut and has great impact resistance.

Next step is to seal the back with static bags and painters (blue) tape. The painters tape goes on the system as it will not harm the finish and the static bags protest the exposed connectors from ESD damage. It is a good idea to have an ESD wrist strap on for this step as there is static built up on tape when you pull it off of the roll. The blue tape doesn't stick real well to the static bags but that is ok as the next steps hold it down.

Now I use the blue tape to seal and secure any doors or openings.

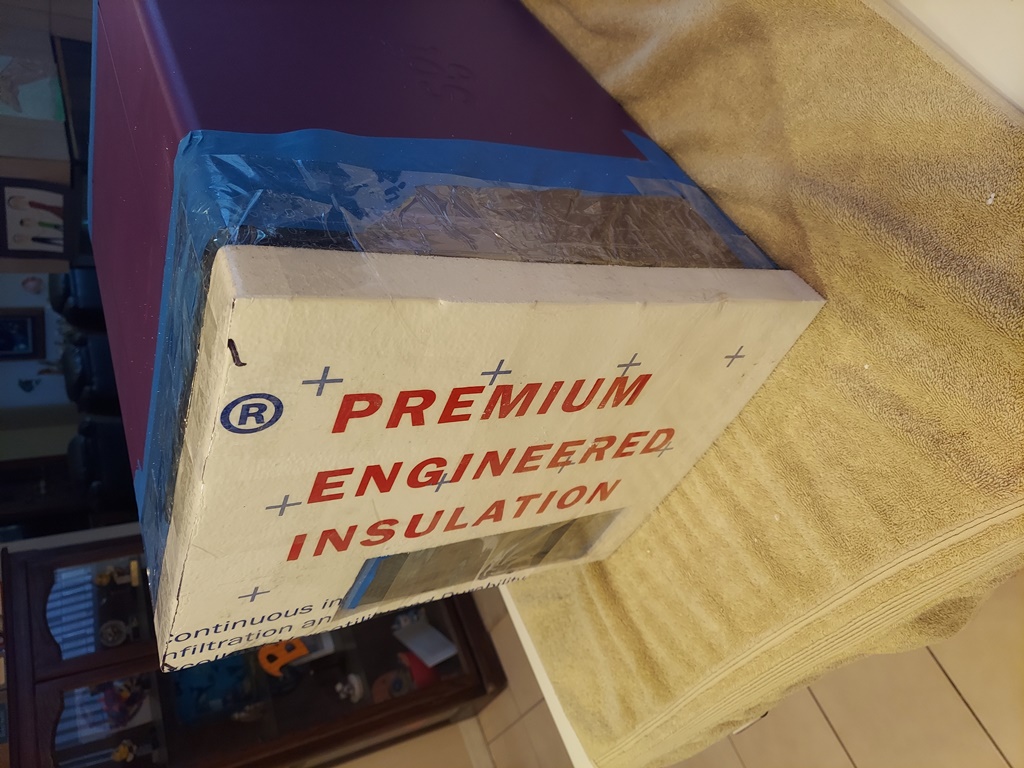

I then create a foam "backplate" that is cut to clear any structure that sticks out. in the case of this Prism or a Tezro that is the fan cage. On the Octane you need to clear the power supply and handle so the backplate will be thicker. You want to make sure that the foam backplate extends just past the part sticking out.

What isn't shown here is that I carve notches in the back plate on the system side for clearance for handles, connectors and any large ridges to enable the backplate to sit as flush as possible to the system back. The Reason for this is so the backplate spreads any impact loads over as much area as possible.

Now stand the machine on it's back and using strong shipping tape secure the back plate to the system. Only allow the shipping tape to hit the backplate and sections covered by the blue tape. Do not let shipping tape stick to the system as it will damage the finish!

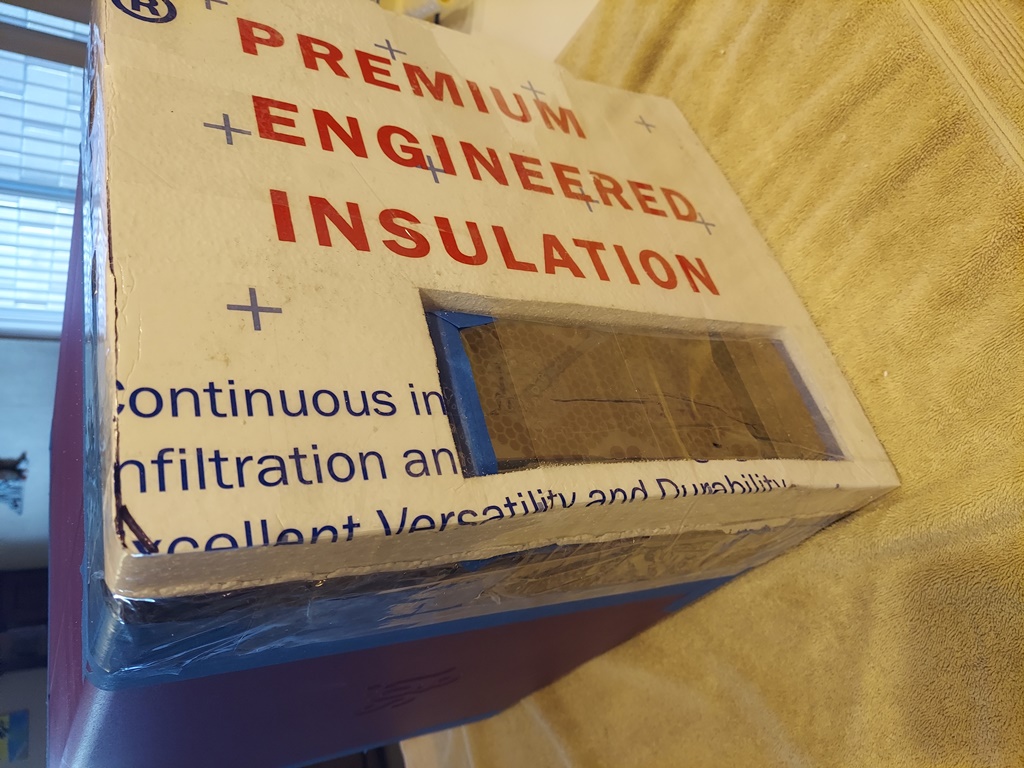

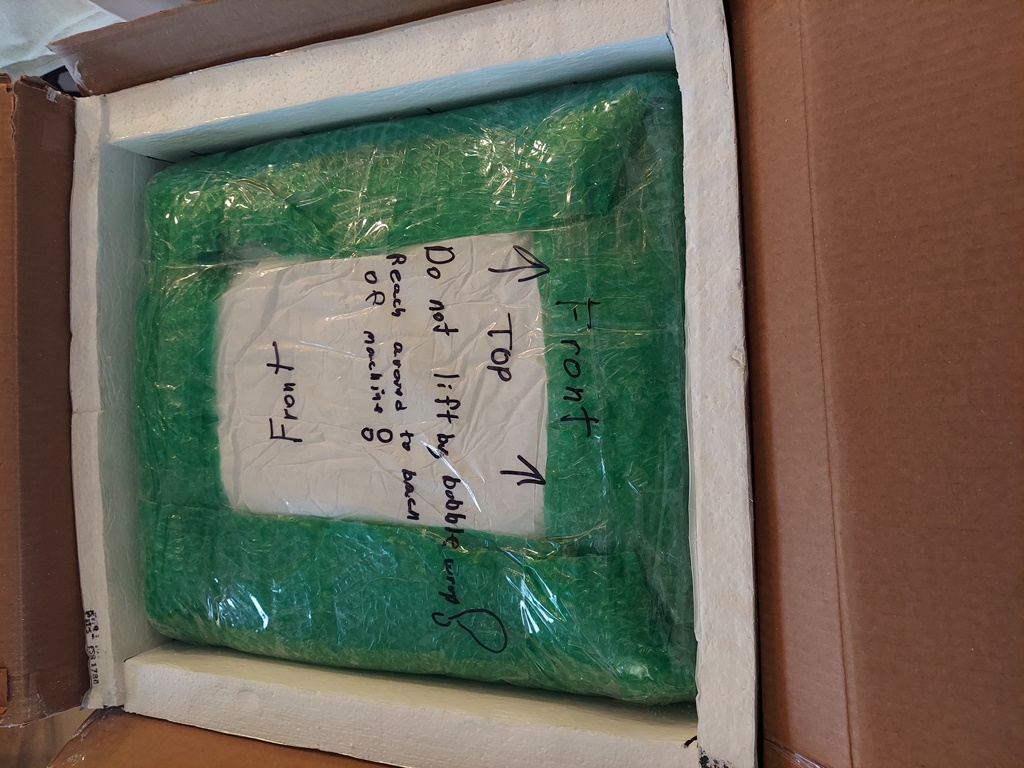

Now wrap the machine in 5 or 6 wraps of small bubble wrap and cover the face with soft tissue paper. then seal and tape what is now the top. I then add instructions to the top of the wrapped system telling the buyer not to lift by the bubble wrap and what side is up. Then I create a box that will hold the system with 1" foam on all sides. this box will go inside of the larger box surrounded by foam. This is required by most shippers and required to get the insurance level required by these machines.

Now add a 1" foam top to the "core". Then cut down the sides of the box to the height required and add some secondary shipping info in case the box is opened by customs. Finish tape the box and then wrap several strips of "filament" tape in both directions to help hold the box together if it is severely abused. Filament tape is the shipping tape with fiberglass strands in it, sometimes called strapping tape.

However, talk to your shipper before you finish seal the box in case they require the contents to be inspected for insurance.